This article is based on a session from our monthly Virtual Brew, where we explored topics like location intelligence, GNSS vs GPS data, and geospatial analytics for smarter pipeline compliance and asset management. You can watch or listen to the full webinar here.

In today’s regulatory environment, pipeline operators face increasing pressure to ensure asset integrity, deliver audit-ready reports, and reduce costly rework in the field. At the heart of these challenges lies a simple truth: location matters.

Accurate GNSS data collection and asset location tracking allows organizations to make smarter, data-driven decisions that support compliance and improve operational efficiency.

That’s where location intelligence comes in. By integrating high-accuracy GNSS (Global Navigation Satellite System) technology with field data collection workflows, operators can connect compliance, GIS (Geographic Information System), and field operations in powerful new ways.

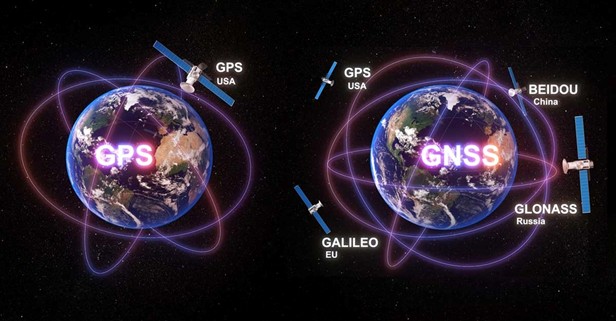

GPS vs. GNSS: Understanding the Difference in Location Intelligence

Most people are familiar with GPS (Global Positioning System), the U.S.-based constellation of satellites used for navigation. But GPS is just one piece of the puzzle.

GNSS is the broader term that includes GPS plus other global constellations:

By combining signals from multiple constellations, modern GNSS devices provide greater accuracy, reliability, and coverage than GPS alone. For pipeline operators, this means faster data collection, higher confidence in results, and fewer repeat site visits.

Why High-Accuracy GNSS Matters for Pipeline Compliance

Integrating GNSS into pipeline compliance workflows is no longer optional—it’s becoming essential. Here’s why:

- Regulatory Confidence: Agencies like PHMSA and DOT require traceable, accurate data. High-accuracy GNSS ensures asset locations and survey records meet regulatory standards.

- Reduced Rework: Accurate location tracking data eliminates costly return trips or unnecessary excavations.

- GIS Integration: GNSS locations easily integrate with your GIS system, allowing for 2D or 3D location modeling of your compliance facilities (assets) and supports enterprise GIS data models (PODS, UPDM, Esri Utility Network), ensuring asset and compliance data feeds directly into decision-making systems.

- Smarter Asset Management: Spatial data becomes a key that links pipeline assets, survey history, and compliance workflows into a unified view.

In short: GNSS captures the precise “where” and powers smarter compliance and risk management decisions across your entire operation.

GNSS Data Collection Tools for Asset Location Tracking

American Innovations software natively supports a wide range of GNSS receivers commonly used in pipeline operations and other asset management, including:

- Juniper Systems Geode series (GNS3H, GNS3M, GNS3S)

- EOS Positioning Systems (Arrow, Skadi)

- American Innovations’ DVM2130 Digital Voltmeter, where the built-in GPS automatically adds a precise time and location stamp to every voltage reading

These receivers connect via Bluetooth to American Innovations’ mobile devices and applications—making high-accuracy GNSS data collection accessible to both field crews and GIS teams with plug and play ease of use.

Correction Services and RTK GNSS: Boosting Accuracy Beyond Satellites

Even with multiple constellations, environmental factors like trees, buildings, or atmospheric interference can impact accuracy. That’s why correction services are used to refine location data:

- Real-Time Kinematics (RTK) GNSS: Uses live internet connections and reference stations to deliver sub-decimeter accuracy in the field. It’s fast and reliable—but requires an active internet connection and sometimes subscription services.

- Post-Processing: Enables offline data collection and applies corrections later using base station data. This is cost-effective and accurate, but slower, with no immediate accuracy confirmation in the field.

- SBAS: Free US-owned satellite correction service that delivers accuracy between 30-60 centimeters.

These methods improve accuracy dramatically. But the newest technology may eliminate the need for correction services altogether.

The Future of Location Intelligence: Galileo High Accuracy Service (GHAS)

A breakthrough development is Galileo High Accuracy Service (GHAS), a next-generation GNSS service being developed in Europe. Using an additional frequency band (L5) with stronger protections against signal interference (also known as multipathing), GHAS can deliver subfoot accuracy (~25 cm, or about 8 inches) without any correction service or subscription.

Key benefits:

- No post-processing required

- No RTK GNSS internet connection or subscription needed

- Two-thirds global coverage, including North America, Central America, Europe, and Africa, with more regions expanding

For pipeline operators, this means:

- Faster setup times—we expect it to take under five minutes to acquire correction signals

- Lower cost of ownership

- Reliable performance even in challenging environments

In other words, the future of location intelligence is here—and it’s cost-effective, accurate, and accessible.

Real-World GNSS Applications in Pipeline Operations

High-accuracy GNSS enables pipeline operators to:

- Locate test stations and CP assets with subfoot precision

- Verify pipeline deviations caused by shifting terrain or climate conditions

- Support cathodic protection surveys with GIS-ready data

- Eliminate errors in field logs and ensure audit-ready records

- Improve data confidence for both compliance reporting and long-term asset management

- Accurately locate buried assets during construction.

One example is a large geographically dispersed gas utility operating in multiple states who worked with us to build a 30-station RTK private network. This network enables them to precisely locate assets and compliance-related features, as well as perform any other field work that requires high-accuracy location services.

Key Questions for Operators to Consider

As GNSS adoption grows, every pipeline organization should ask:

- Who in our organization needs high-accuracy GNSS data?

- Is the spatial data we collect today part of compliance and decision-making?

- Are our compliance, GIS, and field teams aligned on accuracy expectations?

- Do we have the right tools and workflows to support audit-ready reporting?

Answering these questions is the first step toward building a truly spatially intelligent compliance program.

Conclusion: Smarter Compliance Through Location Intelligence

Pipeline compliance isn’t just about meeting regulations—it’s about building a system you can trust. By combining GNSS technology and field data collection with seamless geospatial data integration, operators can:

- Ensure accurate, audit-ready data

- Strengthen compliance workflows

- Improve GIS integration

- Reduce rework and operational costs

At American Innovations, we help pipeline operators leverage highly accurate spatial location in several ways:

CartoPac Digital Asset Management for as-built workflows that captures:

- Who installed or connected the asset into the pipe network (done via Operator Qualification)

- What asset was installed, scanned via an ASTM barcode

- When the work occurred

- Where the asset is located, within inches

- How the asset was connected to other assets in the pipe network, ie, welded, mechanical, etc. (also done via Operator Qualification)

Pipeline Compliance System (PCS) to pinpoint accurate locations for cathodic protection (CP) facilities during CIS (close interval surveys) and other field work. You can also import this data into your GIS to provide a complete picture of pipeline threats and the overall health of your cathodic protection systems.

Field Data Collection (FDC) tools to integrate high-accuracy GNSS into daily workflows.

The result: smarter, more confident decisions at every level of your operation.

Contact us today to learn how American Innovations can help your team harness spatial intelligence for smarter, safer pipeline compliance.

↔