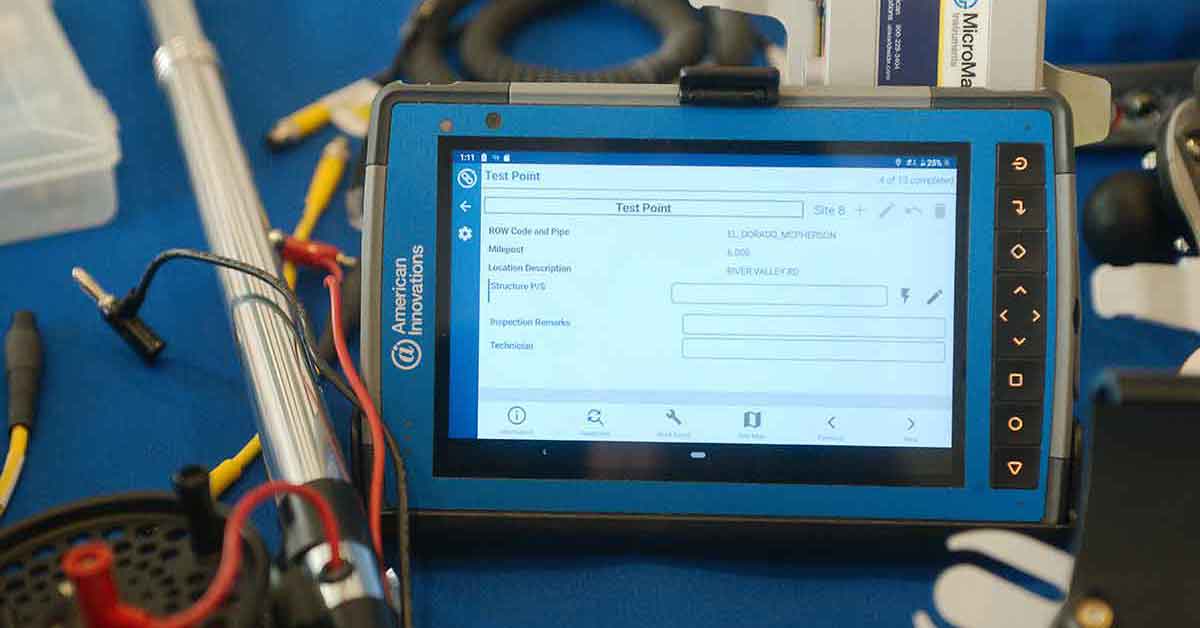

Field Data Collection

Powerful hardware and software for asset safety and compliance.

Request a QuoteField Data Collection Solutions

Read what our customers are saying

Thank you for your interest in Field Data Collection. Fill out the form below and we'll be in touch as soon as possible.

Request a Quote

"*" indicates required fields