In this article, we explore the shifting paradigm where cathodic protection compliance analysis moves from the office to the field. New features in the Field Data Collection (FDC) app allow technicians to perform real-time CP validation against regulatory criteria—like PHMSA’s 49 CFR §192.463—eliminating costly revisits and ensuring audit-ready data before leaving the site.

The Traditional Cathodic Protection Compliance Workflow

For decades, the industry has relied on a reactive workflow for cathodic protection (CP) compliance. As Patrick McLellan outlined at AI World, this approach typically follows a delayed sequence:

- Data Collection: Technicians collect structure readings in the field, often on paper or disconnected devices.

- Transmission to Office: Technicians send data back to the office for analysis in your cathodic protection compliance software, such as the Pipeline Compliance System (PCS).

- Review: Supervisors review the data against criteria, often days or weeks later.

- Feedback Loop: Teams take action only after this delay.

This latency creates significant operational risks. By the time office staff flag an issue—such as a missed reading or a value outside the -850 mV criteria—the technician has already moved to another job. This delay forces supervisors into a difficult choice: accept the compliance risk or spend time and money sending someone back to the field to correct the data. Neither of which support efficient or defensible cathodic protection compliance.

The New Paradigm: Real-Time Cathodic Protection Validation

By embedding office-level compliance logic directly into the Field Data Collector (FDC) app, operators can validate cathodic protection compliance in real time—while standing at the test point. Instead of waiting days or weeks for office review, FDC immediately evaluates readings against your specific Test Point Protection Criteria (TPPC).

This feature does more than check for “good” or “bad” numbers; it validates against federal regulations. For instance, the system checks against PHMSA 49 CFR §192.463, verifying if readings meet the -850 mV "instant-off" criteria or the 100 mV polarization shift.

As technicians take readings, the software instantly calculates compliance status. Visual indicators allow field staff to see immediately if a test point passes, fails, or requires further investigation. This instant feedback loop empowers technicians to troubleshoot issues on the spot—cranking a rectifier or fixing a test lead—rather than generating a work order for a return trip.

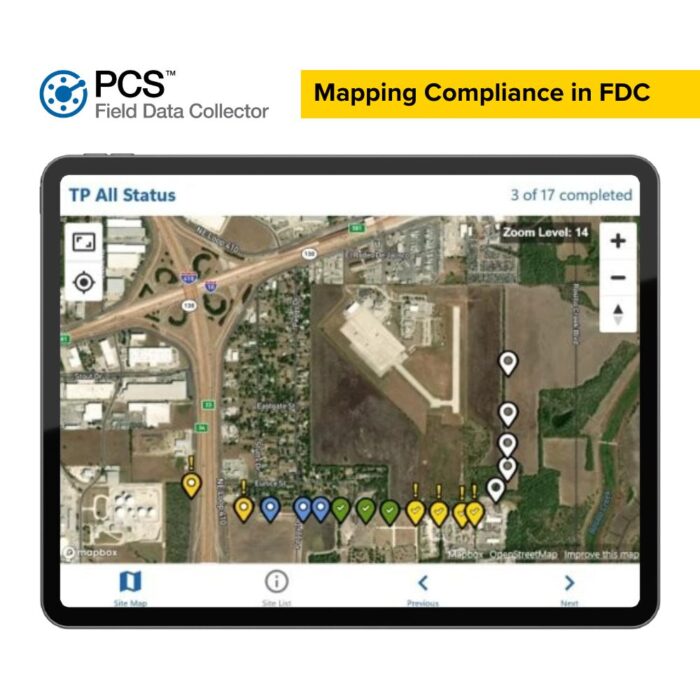

Geospatial Analysis & Map-Based Insights

Compliance involves patterns, not just single data points. The updated FDC introduces map-based insights that visualize compliance status across the entire route.

The system color-codes facilities for instant status recognition:

- Green: Surveyed and compliant

- Blue: Visited

- White: Not visited

- Yellow: Criteria violation

This allows technicians and supervisors to spot geospatial trends. If a cluster of test points suddenly shows non-compliance, it might indicate a localized environmental issue, new construction interference, or a system failure. Seeing this on a map allows for immediate, data-driven decisions that technicians might miss when looking at rows of numbers in a spreadsheet.

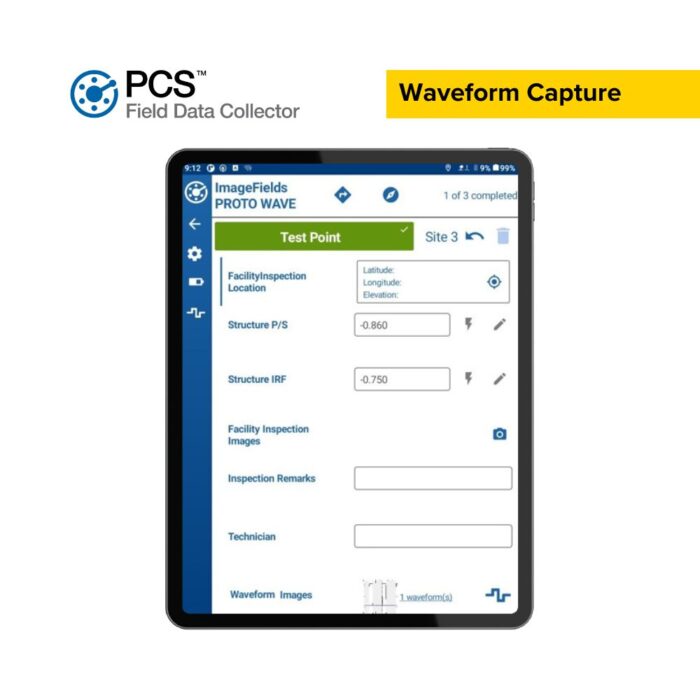

Integrated Waveform Capture

Historically, pairing waveform data with inspection records was a disjointed process. The new workflow integrates waveform capture directly into the inspection survey.

Technicians can now capture multiple waveforms per inspection and correlate them directly with the voltage reading. This seamless integration allows for troubleshooting complex CP systems and provides the "full picture" to defend cathodic protection compliance data during audits. Technicians can use this capability to capture "before and after" waveforms to document adjustments they make in the field.

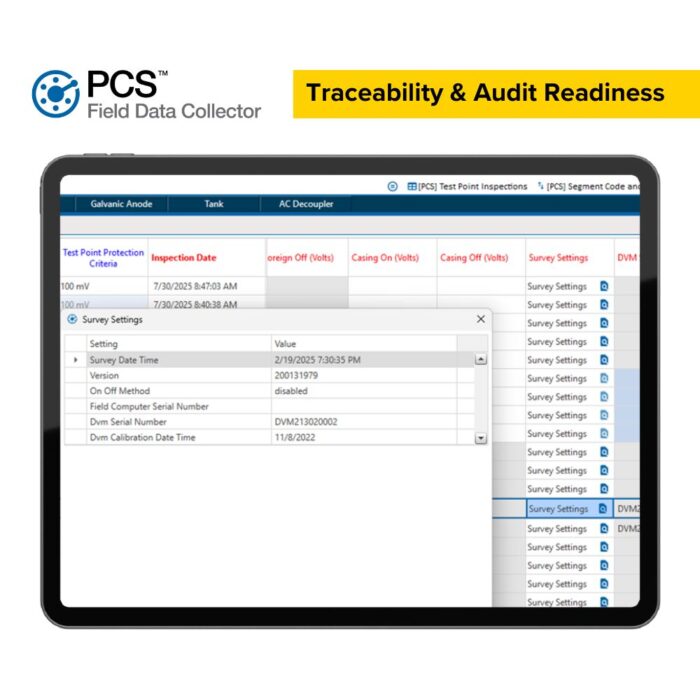

Improved Traceability and Audit Readiness

High-quality compliance data requires knowing the "who, what, when, and how." To support better audit readiness, FDC now captures granular metadata at the inspection level.

This includes the specific device used, its calibration date, and the survey settings applied at the exact moment of capture. This traceability ensures that if an auditor asks, "How do you know this reading is valid?" you hold the specific timestamped evidence linked directly to the record.

Conclusion

Moving cathodic protection compliance analysis to the field strengthens the office review process rather than replacing it. By giving field teams the tools to validate data and visualize compliance in real-time, American Innovations helps operators close the feedback loop faster, reduce operational costs, and maintain a higher standard of safety and compliance.

↔