MORE RESOURCES

What is PCS?

Whether you work in gathering, liquid products, or distribution, Pipeline Compliance

System (PCS) software provides the data you need to protect your assets.

PCS captures, analyzes, and reports compliance data across your pipeline network so you

can manage your corrosion program like never before.

How PCS Supports Your Pipeline Compliance

Continuous Compliance

PCS software automates data collection, analysis, planning, scheduling, and reporting to manage pipeline programs at all levels. PCS also provides integrated compliance with PHMSA & DOT regulatory standards, while keeping pace with the expanding Mega Rule.

Pre-Built and Customizable Reporting

All PCS modules include extensive reporting to help manage your compliance needs. Each report can be fully customized and shared automatically based on your organizational needs.

Workflow Integration

The PCS ecosystem is built to work seamlessly with other American Innovations solutions, including our proprietary field data collection hardware, PCS Survey Manager, Bullhorn® Remote Monitors, and third-party systems, such as GIS, work management, and maintenance management.

PCS Modules: An Array Of Pipeline Compliance Features

With an array of features, such as specific reporting and critical compliance criteria based on the module, PCS lets you effectively manage specific types of survey data from a central database you and your team can access from the field and the office.

FEATURED PRODUCT

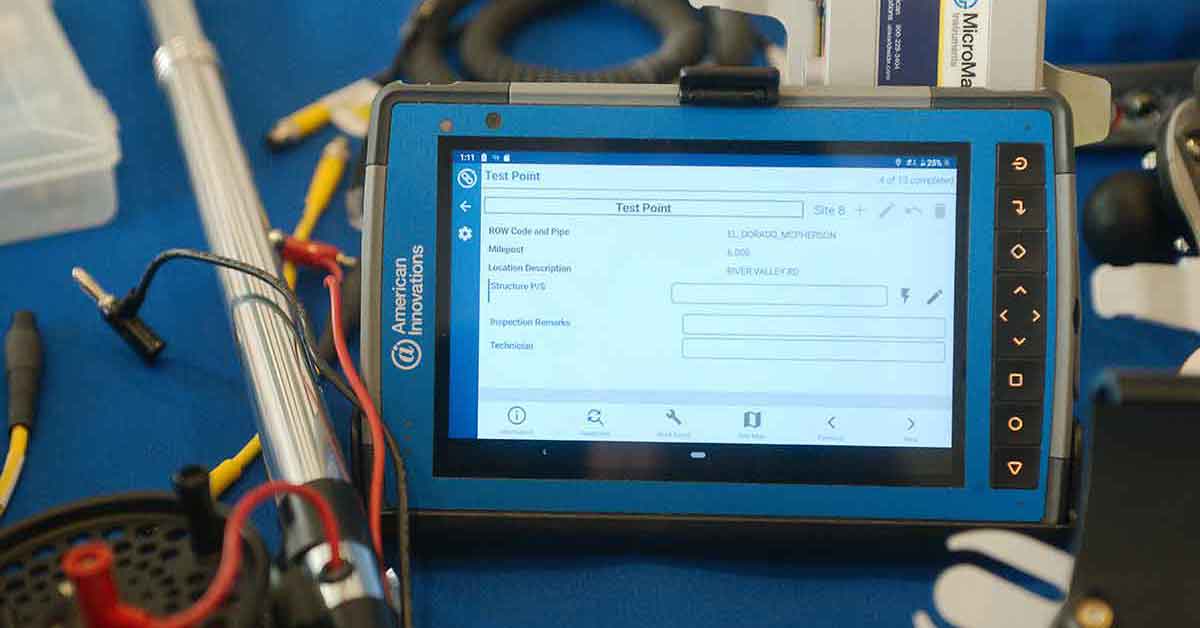

PCS Survey Manager

PCS Survey Manager enables users of PCS and our integrated field data collection suite to validate, map, and wirelessly sync survey data from the field to the office.

Quickly identify trends, pinpoint areas for further investigation, optimize routes, and collaborate with team members to ensure data quality. Easily correct and align indirect survey data to build reliable, continuous day plots.

PCS Survey Manager is available on any device, anywhere you need it, as long as you have an active internet connection.